Description

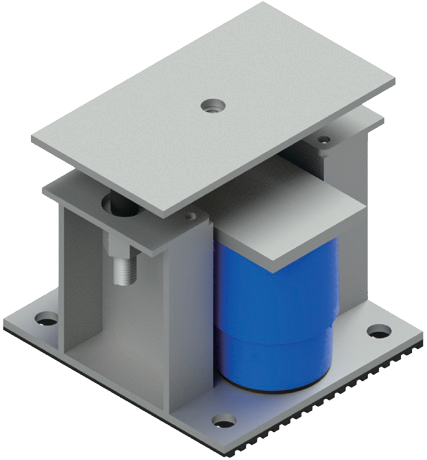

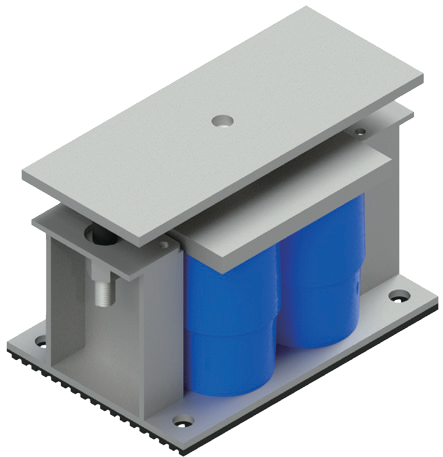

The AO-TYPE is a floor-mounted spring vibration isolator designed for serious industrial equipment. It uses a high-performance steel spring with a fixed 40 mm working deflection, which gives strong vibration reduction without making equipment feel “floaty.” Under normal rated load, the spring keeps a safe geometry and still has over 50% extra compression travel left for safety.

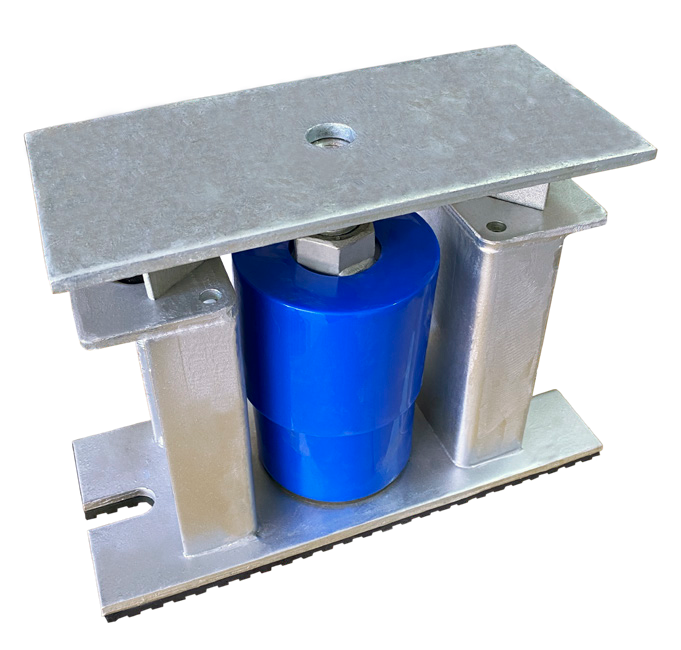

The outer frame is made from hot-dip galvanized steel, so it holds up outdoors and in nasty mechanical rooms without turning into rust art. The spring itself is powder-coated and tested to survive more than 1000 hours of salt spray, and it’s wrapped in a tough PP plastic shell to protect it from impacts and corrosion.

At the bottom, there’s a 6 mm thick anti-slip rubber pad with a friction coefficient over 0.9, so once you place it, it stays put. There’s also a built-in leveling bolt so you can fine-adjust height and lock equipment down properly. The travel-limit bolt is designed with a 12 mm safety gap so metal parts don’t smash into each other during movement.

AO-TYPE isolators come in three frame sizes (AO1, AO2, AO4) and many load ratings, from small 80 kg setups all the way up to 4000 kg per unit. All models use the same 40 mm spring deflection for consistent vibration control across sizes.

Typical uses include chillers, cooling towers, generators, pumps, HVAC units, and any heavy floor-mounted equipment where vibration, noise, or structure-borne rumble is a problem. Stainless steel versions are also available if you need extra corrosion resistance.

In short: it’s a simple, tough, no-nonsense way to stop big machines from shaking everything around them. Built to survive, built to isolate, and built for real equipment—not toy setups.